CO SERIES

Cement-On Surface Thermocouples

€302,81

CO1-K

-

Response Time in Milliseconds

-

Made from 0.0005" Foil and 0.010" Diameter Thermocouple Wire

-

Very Low Thermal Inertia

-

Four Calibrations "K", "E", "J" and "T"

-

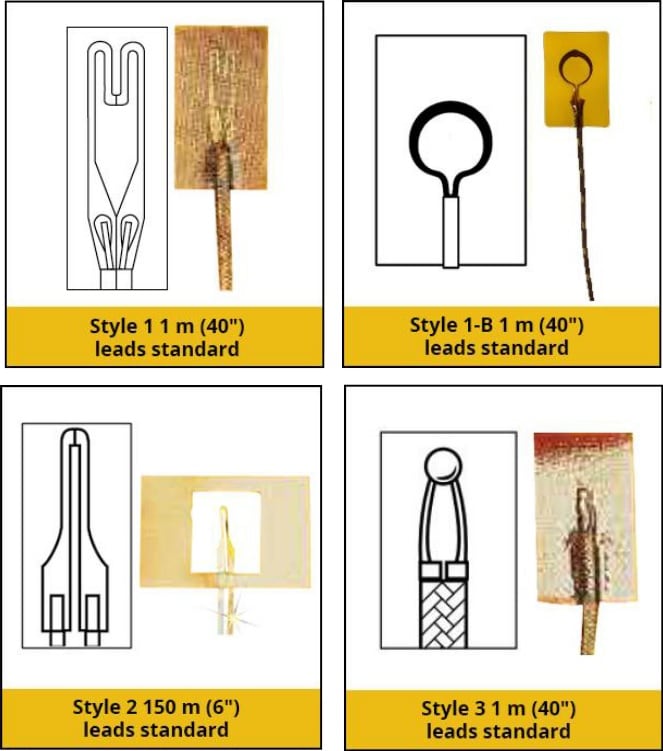

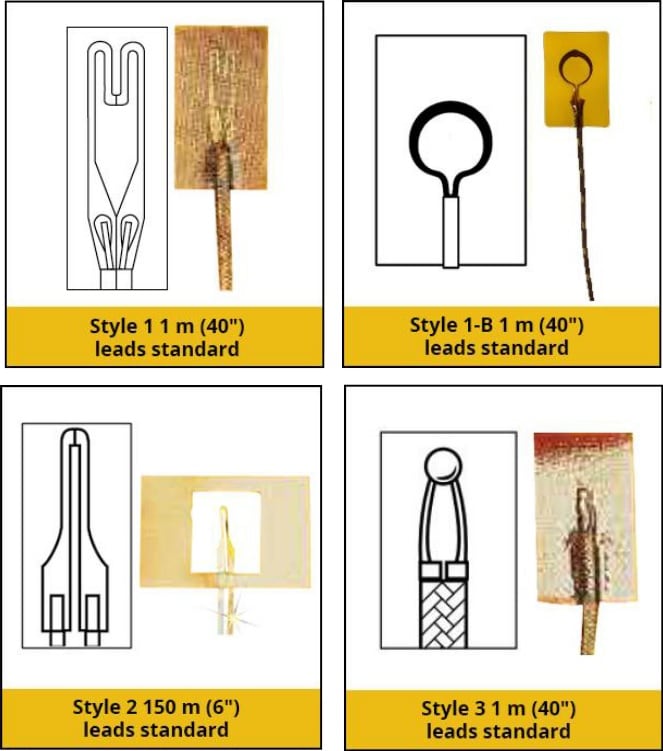

Three Styles Ideal for Surface Measurement

-

Lead lengths: Style 1 and 3 are 1m (40") long. Style 2 is 150mm (6") long, standard. Additional lengths are available on request.

Thermoelemente - Verwandte Produkte anzeigen

Beschreibung

OMEGA introduces its Cement-On, fast response Foil Thermocouples for fast surface temperature measurement applications in three convenient styles. Styles 1, 2 are made from 0.005" thermocouple alloy & Style 1- B made by 0.008" by a special process where the butt welded thermocouple junction Styles 1, and 2 are flat, extremely low inertia construction and are an ideal means of measuring the temperature of both flat and curved metals, plastic and ceramic surfaces where very fast response is desired.

OMEGA's Cement-On Style 1,1-B and 2 Foil Thermocouples are fabricated from ANSI "Special Limits of Error" grade thermocouple materials in "K", "E" and "T" calibrations and yield accurate temperature indication when used with standard thermocouple instrumentation. Styles 1, 1-B and 2 have the fastest response. Style 3 is an economy version constructed from 0.010" diameter bead welded standard limit of error thermocouple wire. It should be used where extremely fast response is not essential.

Cement-On Style 1 thermocouples are the easiest to install. The foil sensor is embedded between two paper-thin, glass reinforced high-temperature polymer laminates which both support and electrically insulate the foil section as well as provide a flat surface for cementing. The polymer/glass laminate, in general, determines the maximum temperature of the construction which is 260°C (500°F) continuous and up to 370°C (698°F) for short duration. Each Style 1 unit includes 1m (40")of glass braid insulated 30 gauge thermocouple wire which is bonded to the foil and strain relieved by laminate. An application instruction sheet accompanies each packaged Cement-On type thermocouples. Cement-On Style 1 thermocouples are the easiest to install. The foil sensor is embedded between two paper-thin, glass reinforced high-temperature polymer laminates which both support and electrically insulate the foil section as well as provide a flat surface for cementing. The polymer/glass laminate, in general, determines the maximum temperature of the construction which is 260°C (500°F) continuous and up to 370°C (698°F) for short duration. Each Style 1 unit includes 1m (40")of glass braid insulated 30 gauge thermocouple wire which is bonded to the foil and strain relieved by laminate. An application instruction sheet accompanies each packaged Cement-On type thermocouples. |

|

| Economical version Cement-On Style 1-B thermocouples are the easiest to install. The thin sensor (0.008") is embedded between two thin, high-temperature polymer laminates which both support and electrically insulate the foil section as well as provide a flat surface for cementing. The polymer/glass laminate, in general, determines the maximum temperature of the construction which is 260°C (500°F) continuous and up to 370°C (698°F) for short duration. Each Style 1 unit includes 1m (40")of glass braid insulated 30 gauge thermocouple wire which is bonded to the foil and strain relieved by laminate. An application instruction sheet accompanies each packaged Cement-On type thermocouples. |

|

OMEGA Cement-On Style 2 thermocouples are recommended where extremely fast surface temperature measurement response time is a requirement. Intimate thermal coupling for this style is achieved by directly bonding the foil junction area to the surface to be measured. For ease of handling, the foil leads come fastened to a polyimide film frame which is a tough, flexible, dimensional, stable material rated for 260°C (500°F) continuous service. During application, the foil thermocouple can be peeled from the frame or released by the application of heat. As an alternative, portions of the frame may be cut away by scissor or knife. OMEGA Cement-On Style 2 thermocouples are recommended where extremely fast surface temperature measurement response time is a requirement. Intimate thermal coupling for this style is achieved by directly bonding the foil junction area to the surface to be measured. For ease of handling, the foil leads come fastened to a polyimide film frame which is a tough, flexible, dimensional, stable material rated for 260°C (500°F) continuous service. During application, the foil thermocouple can be peeled from the frame or released by the application of heat. As an alternative, portions of the frame may be cut away by scissor or knife.

The 150 mm (6") uninsulated foil leads are of 0.05 mm (.002") material and thus are fragile and should be handled with care during installation. NOTE: It is imperative that the leads be electrically insulated from each other as well as being mechanically supported. This can be achieved, for example, by laying and brushing the leads into a layer of insulating cement or epoxy. Before doing this on electrically conductive surfaces, it is best to lay down and let dry, a thin layer of the cement to ensure that the leads are insulated from the surface. Insulated thermocouple lead wire can be bonded to the foil leads by silver soldering, or resistance welding. Thirty gages or smaller lead wire is suggested. An application instruction sheet accompanies each package of thermocouples.

Cementing of the junction and lead may be achieved by using OMEGA™ CC high-temperature cement for temperatures above 260°C (500°F); OMEGABOND™ OB-101 or OB-200 epoxies for temperatures below 260°C (500°F). Please note more care is required to install the Style 2 than Style 1 or 3. It is suggested that at least one additional unit be ordered as some experimentation may be necessary to learn the technique of application for these thermocouples. |

|

Style 3 thermocouples are constructed of 30 gages (0.010") diameter "Standard Limits of Error" wire. The welded bead thermocouple is embedded in a paper-thin laminate intended for surface applications by bonding with an added adhesive. Color-coded, glass braid insulated 1m (40") leads are supplied. Style 3 probes can be used over the range of -190 to 370°C (-310 to 698°F) depending on the adhesive or cement used, the time of exposure and the environment. Style 3 thermocouples are constructed of 30 gages (0.010") diameter "Standard Limits of Error" wire. The welded bead thermocouple is embedded in a paper-thin laminate intended for surface applications by bonding with an added adhesive. Color-coded, glass braid insulated 1m (40") leads are supplied. Style 3 probes can be used over the range of -190 to 370°C (-310 to 698°F) depending on the adhesive or cement used, the time of exposure and the environment. |

| Model No. |

Style |

Thermocouple Type |

Length

mm (inches) |

Maximum Temperature °C* (°F) |

| Continuous |

600 hr. |

10 hr. |

| CO1-K |

1 |

K CHROMEGA™-ALOMEGA |

1m (40") |

260 (500) |

315 (600) |

370 (700) |

| CO1-E |

E CHROMEGA™-Constantan |

1m (40") |

260 (500) |

315 (600) |

370 (700) |

| CO1-T |

T Copper - Constantan |

1m (40") |

150 (300) |

205 (400) |

260 (500) |

| CO1-K-B |

1-B |

K CHROMEGA™-ALOMEGA |

1m (40") |

260 (500) |

315 (600) |

370 (700) |

| CO2-K |

2 |

K CHROMEGA™-ALOMEGA™ |

150 mm (6") |

540 (1000) |

540 (1000) |

650 (120) |

| CO2-E |

E CHROMEGA™-Constantan |

150 mm (6") |

425 (800) |

425 (800) |

540 (1000) |

| CO2-T |

T Copper-Constantan |

150 mm (6") |

150 (300) |

150 (300) |

260 (500) |

| CO3-J |

3 |

J Iron - Constantan |

1m (40") |

260 (500) |

370 (700) |

370 (700) |

| CO3-K |

K CHROMEGA™-ALOMEGA™ |

1m (40") |

260 (500) |

370 (700) |

370 (700) |

| CO3-E |

E CHROMEGA™-Constantan |

1m (40") |

260 (500) |

370 (700) |

370 (700) |

| CO3-T |

T Copper-Constantan |

1m (40") |

205 (400) |

260 (500) |

370 (700) |

View the Thermocouple Accuracy and Colour Code charts

*Alle Preisangaben in Euro.

Anmerkung: Response time when "grounded" or "cemented" to surface: Style 1 —10 to 20 milliseconds, Style 2 — 2 to 5 milliseconds, Style 3 — 300 milliseconds.

The response time or "time constant" is the time required to reach 63.2% of an instantaneous temperature change.

Additional length wire can be ordered for Styles 1 and 3, add $6.00 per 300 mm (12"), for Style 2 add $12.00 per 300 mm (12")

The temperature range high limits given are greatly influenced by environmental conditions, installation method, accuracy and lifetime requirements and may vary from the general guidelines listed in the table.

Style 1 and 3 cannot be used with CC High Temperature Cement; CC Cement will break down insulation.

(OPTIONS SHOWN IN THIS "NOTE" ABOVE ARE PRICED IN US$)

Ordering Example: (1) CO4-K-40 Type K (CHROMEGA™-ALOMEGA™) 1 m (40''), cement-on thermocouple., €134,13 plus (1) CO1-K Type K ( CHROMEGA™-ALOMEGA™) 1m (40''), cement on Thermocouple, €302,81, €134,13 + 302,81 = €436,94

Modellkonfigurator

Stellen Sie Ihre Modellnummer zusammen

Optionsbeschreibungen:

(1)

Style Wählen Sie:1 für 1 m (40in) leads standard

2 für 150 mm(6in) lead standard

3 für 1 m (40in) lead standard

(2)

Thermcouple Type Wählen Sie:-K für CHROMEGA™-ALOMEGA™

-E für CHROMEGA™-Constantan

-T für Copper - Constantan

-J für Iron - Constantan

Anmerkung: Nicht alle Optionen können miteinander kombiniert werden, die gültigen Teilenummern entnehmen Sie bitte dem Datenblatt.

Zugehörige Dokumentation:

Download

Ultrafast Surface Foil Thermocouples

Download

CO1, CO1, CO3 - Cement on Thermocouples

SCHLIESSEN

SCHLIESSEN

Cement-On Style 1 thermocouples are the easiest to install. The foil sensor is embedded between two paper-thin, glass reinforced high-temperature polymer laminates which both support and electrically insulate the foil section as well as provide a flat surface for cementing. The polymer/glass laminate, in general, determines the maximum temperature of the construction which is 260°C (500°F) continuous and up to 370°C (698°F) for short duration. Each Style 1 unit includes 1m (40")of glass braid insulated 30 gauge thermocouple wire which is bonded to the foil and strain relieved by laminate. An application instruction sheet accompanies each packaged Cement-On type thermocouples.

Cement-On Style 1 thermocouples are the easiest to install. The foil sensor is embedded between two paper-thin, glass reinforced high-temperature polymer laminates which both support and electrically insulate the foil section as well as provide a flat surface for cementing. The polymer/glass laminate, in general, determines the maximum temperature of the construction which is 260°C (500°F) continuous and up to 370°C (698°F) for short duration. Each Style 1 unit includes 1m (40")of glass braid insulated 30 gauge thermocouple wire which is bonded to the foil and strain relieved by laminate. An application instruction sheet accompanies each packaged Cement-On type thermocouples. OMEGA Cement-On Style 2 thermocouples are recommended where extremely fast surface temperature measurement response time is a requirement. Intimate thermal coupling for this style is achieved by directly bonding the foil junction area to the surface to be measured. For ease of handling, the foil leads come fastened to a polyimide film frame which is a tough, flexible, dimensional, stable material rated for 260°C (500°F) continuous service. During application, the foil thermocouple can be peeled from the frame or released by the application of heat. As an alternative, portions of the frame may be cut away by scissor or knife.

OMEGA Cement-On Style 2 thermocouples are recommended where extremely fast surface temperature measurement response time is a requirement. Intimate thermal coupling for this style is achieved by directly bonding the foil junction area to the surface to be measured. For ease of handling, the foil leads come fastened to a polyimide film frame which is a tough, flexible, dimensional, stable material rated for 260°C (500°F) continuous service. During application, the foil thermocouple can be peeled from the frame or released by the application of heat. As an alternative, portions of the frame may be cut away by scissor or knife. Style 3 thermocouples are constructed of 30 gages (0.010") diameter "Standard Limits of Error" wire. The welded bead thermocouple is embedded in a paper-thin laminate intended for surface applications by bonding with an added adhesive. Color-coded, glass braid insulated 1m (40") leads are supplied. Style 3 probes can be used over the range of -190 to 370°C (-310 to 698°F) depending on the adhesive or cement used, the time of exposure and the environment.

Style 3 thermocouples are constructed of 30 gages (0.010") diameter "Standard Limits of Error" wire. The welded bead thermocouple is embedded in a paper-thin laminate intended for surface applications by bonding with an added adhesive. Color-coded, glass braid insulated 1m (40") leads are supplied. Style 3 probes can be used over the range of -190 to 370°C (-310 to 698°F) depending on the adhesive or cement used, the time of exposure and the environment.